RESEARCH PROGRAMMES

P4: Nanomagnetism and Critical Raw Materials

RESEARCH SUPERVISOR(S)

Dr Alberto Bollero

Research Group website: https://nanociencia.imdea.org/division-permanent-magnets-applications

Dr Gorka Salas

Research Group website: https://nanociencia.imdea.org/magnetic-nanoparticles/group-home

RESEARCH TOPIC DESCRIPTION

Solid oxide fuel cells (SOFCs) are one of the most promising renewable energy devices and green technologies [1]. This next-generation power system makes possible achieving high-energy conversion efficiencies using alternative fuels (e.g. hydrogen, natural gas, biogas and solid carbon) accompanied by a minimum carbon dioxide production and no pollutant product. Reduction of the operating temperature in SOFCs will allow their commercialisation as portable power source and will open the path to their integration in electric vehicles.

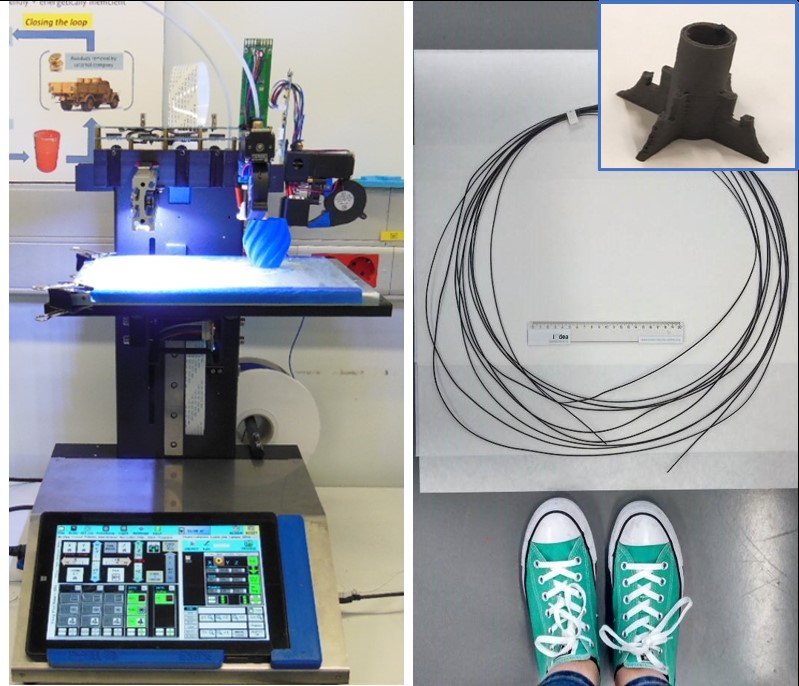

3D-SOLCELL aims at the fabrication of a new generation of green 3D-printed SOFCs with enhanced efficiency through optimized geometries, by combining two advanced manufacturing techniques: inkjet for the fabrication of the cathode (lanthanum strontium ferrite) and Fused Filament Fabrication (FFF) for the fabrication of the anode (Ni/YSZ), making use of IMDEA’s knowledge on the chemical synthesis of composites with a high-load particle content (> 80wt.%) [2].

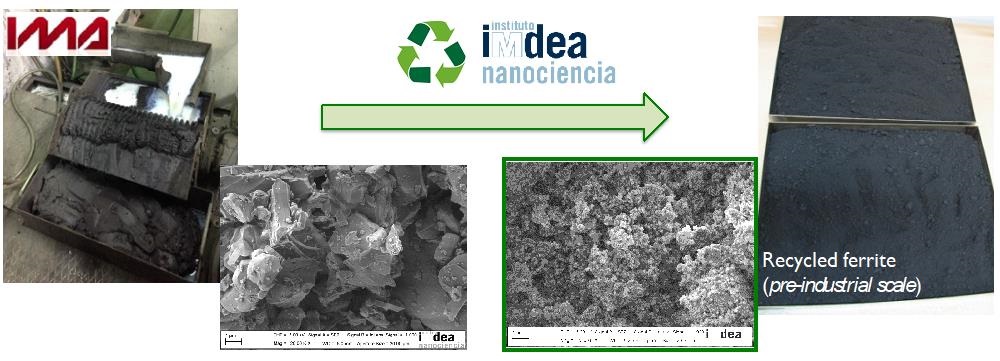

The precursor for fabrication of the cathode will be ferrite powder obtained through a green (chemicals-free) recycling procedure developed by IMDEA Nanociencia [3], followed by compositional adjustment by addition of the corresponding metal salt or precursor. Alternatively, lanthanum strontium ferrite nanoparticles will be prepared by bottom-up approaches for comparison. The anode material will be synthesized by ball milling of the elemental constituents. Performance of SOFCs is influenced by morphology, microstructure and particles distribution in the electrodes. Optimization of these material parameters will be possible by application of the self-developed “flash-milling” method, providing a homogeneous submicrometer particle size in record milling times (< 5 min) [3,4].

[1] R.M. Ormerod, Chem. Soc. Rev. 32, 17 (2003).

[2] E.M. Palmero et al., Addit. Manuf. 33, 101179 (2020).

[3] A. Bollero et al., ACS Sustainable Chem. Eng. 5(4), 3243 (2017).

[4] F.J. Pedrosa et al., RSC Adv. 6, 87282 (2016).

POSITION DESCRIPTION

The proposed research combines materials and technology development to build a green technological horizon, contributing to the EU Green Deal objectives. The activities are to be carried out in IMDEA Nanociencia’s research teams leaded by Dr Alberto Bollero (nanomagnetism and sustainability) and Dr Gorka Salas (synthesis of nanoparticles), in close collaboration with research centres and companies covering from fabrication of ceramic and metal powder to 3D-printing of functional elements.

A typical background would be a PhD in Chemistry, Physics, Materials Science or Engineering, with demonstrated excellent research and technological achievements in the field of materials science focused on energy applications (experience in electrochemistry). Research and technological development should be oriented to produce novel solid oxide fuel cells, and the fabrication of prototypes to demonstrate their functionality.

The researcher will have the opportunity of working in a multidisciplinary scientific environment at IMDEA Nanociencia (Severo Ochoa Center of Excellence) and in the framework of international projects. A close collaboration with the groups leaded by Dr G. Salas and Dr A. Bollero will make possible the combination of expertise on the synthesis of functional nanoparticles and composites, design of materials with tuneable properties, advanced and sustainable fabrication techniques and construction of prototypes. This fruitful combination of expertise will ease the creation of a new research line at IMDEA Nanociencia with objectives well aligned with the strategic goals of the centre and with the EU technological and environmental priorities.

PARTNER ORGANIZATIONS

The following secondments are considered:

- 2 month secondment at the company: Ingeniería Magnética Aplicada (IMA, Spain). Aim: Preparation of the strontium ferrite precursor to be used in the fabrication of the cathode through recycling of ceramic waste based on the method developed by IMDEA Nanociencia.

- 3 month secondment at the research center: Institute of Metals and Technology(IMT, Slovenia). Aim: Application of selective laser sintering to fabricate the electrodes of the cells and establish a comparison on performance based on the use of the different advanced manufacturing techniques here proposed. This activity will allow establishing a correlation between morphology, microstructure and performance (efficiency).

IMDEA’s recycling procedure of ferrite at an industrial environment (IMA) to be applied in 3D-SOLCELL for the production of the cathode precursor of the fuel cell.

3D-printing of functional elements by Fused Filament Fabrication (FFF) using meters long filament extruded from a high-load particle composite synthesized at IMDEA Nanociencia. The anode of the fuel cell will be fabricated by FFF in 3D-SOLCELL.